SCREEN SEPARATORS

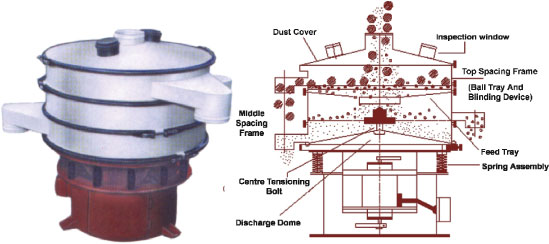

STAR TRACE Screen Separator is a unique particle size gradeable separator

designed for greater capacity per metre square of screening area &

over size material discharge with relatively much less percentage fines

than other screening machines.

|

|

WORKING PRINICPLE

The top weight on the motor shaft rotates in a plane close to the centre

of the mass of assembly. Rotation of the top eccentric weight creates

vibration in the horizontal plane which causes material to move across

the screen cloth to periphery. Increasing the top eccentric mass, increases

the horizontal throw, causing oversize material to discharge at a faster

rate. The bottom eccentric weight rotates below the centre of mass, creating

tilt on the screen, giving vibration in vertical & tangential planes.

Increasing the vertical component of motion, which promotes turn over

of material on the screen surface helping maximum quantity of undersize

material to pass through the screen. The vertical motion also minimizes

blinding of screen by “near size” particles. The tangential component

of motion is controlled by the angle of lead given to bottom weights with

relation to top weight. Variation in lead angle controlled the spiral

pattern of material travel over the screen cloth. Speed &flow pattern

of material travel over the screen cloth can be set by the operator for

maximum throughout & screening efficiency for any screen able product....

wet or dry...coarse or fine… Heavy or light… hot or cold. Typical material

passes rapidly through the screen during its travel to the periphery.

The over size material get continuously discharged through a tangential

outlet.

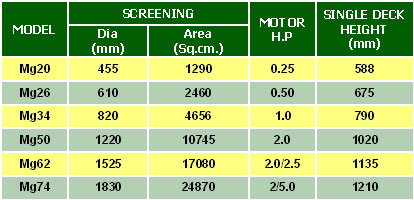

MODELS AND SPECIFICATION